Do you interested to find 'decorative bright chromium plating essay'? Here, you will find all the stuff.

Table of contents

- Decorative bright chromium plating essay in 2021

- Google scholar

- Chrome plating near me

- Electroplating pdf

- Electroplating handbook pdf

- What is electroplating

- Trivalent chromium plating

- Electroplating for decorative applications: recent trends in research and development

Decorative bright chromium plating essay in 2021

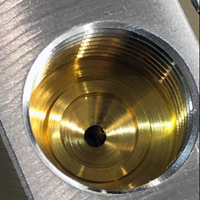

This picture shows decorative bright chromium plating essay.

This picture shows decorative bright chromium plating essay.

Google scholar

This image shows Google scholar.

This image shows Google scholar.

Chrome plating near me

This picture shows Chrome plating near me.

This picture shows Chrome plating near me.

Electroplating pdf

This picture demonstrates Electroplating pdf.

This picture demonstrates Electroplating pdf.

Electroplating handbook pdf

This picture demonstrates Electroplating handbook pdf.

This picture demonstrates Electroplating handbook pdf.

What is electroplating

This image illustrates What is electroplating.

This image illustrates What is electroplating.

Trivalent chromium plating

This image representes Trivalent chromium plating.

This image representes Trivalent chromium plating.

Electroplating for decorative applications: recent trends in research and development

This picture representes Electroplating for decorative applications: recent trends in research and development.

This picture representes Electroplating for decorative applications: recent trends in research and development.

What kind of plating can you use on stainless steel?

Chromium plating can only be done directly on stainless steel while a nickel passes through the pre-plating process before chromium plating. Many or a layer of copper or nickel may come before the deposits of chromium owing to the reason behind the plating.

Why is chromium used as an electrodepositing metal?

The note-worthy attributes of chromium as a metal used for electrodepositing are the decorative and protective properties it posses. Chromium, when deposited, can resist tarnishing, scratches, wear and tear as well as corrosion. Another vital reason for high retentivity of chromium in electroplating is its high lubricating nature.

How is chromium plating used in decorative applications?

Chromium Plating. An overview of decorative and hard chromium electroplating processes. In decorative applications the chrome is plated as a thin (0.25–0.8 μm) layer over nickel to provide an economical and highly corrosion resistant deposit. Fluoride-catalyzed processes are used with sulfate.

What is the role of lead in a chromium plating tank?

In a chromium plating tank, the lead anodes serve two purposes: as the positive electrode and to maintain the solution in satisfactory balance by re-oxidizing the trivalent chromium to chromic acid. The anode area should be about 20 percent greater than the area of the normal plating load.

Last Update: Oct 2021

Leave a reply

Comments

Ivanelle

24.10.2021 11:32Cuprostar nc provides letter a semi-bright copper bank deposit that is appropriate either as letter a strike or primary copper layer for nickel and atomic number 24 plating clepo sp cyanide-free pyrophosphate pig as copper smash is the all but commonly used operation for plating effortful substrates on brand and special application program for pop.